Smart manufacturing starts with intelligent automation and real-time data insights.

From factory floor to cloud—digitize every step of your manufacturing process.

Future-ready factories run on AI, IoT, and scalable digital infrastructure.

Deliver more with less through intelligent manufacturing technologies.

Manufacturing Industry innovation

We are driving the future of manufacturing through advanced digital technologies like AI, IoT, robotics, and cloud computing. Real-time decision-making that revolutionize how production is managed

Our solutions help manufacturers modernize their legacy systems into agile . Empowers enterprises to boost productivity and drive long-term, sustainable growth by Tiso studio.

Digital Transformation in Manufacturing Industry

Intelligent Automation & Smart Manufacturing

Automating repetitive and complex manufacturing tasks with AI, machine learning, and robotics helps streamline production, minimize human error, and boost output. From robotic assembly lines and AI-driven quality control to real-time machine monitoring and digital workflows, intelligent automation empowers manufacturers to increase efficiency and reduce operational costs.

Connected Supply Chains & Real Visibility

A digitally connected supply chain improves end-to-end visibility, enhances forecasting accuracy, and reduces delays. Through IoT sensors, cloud platforms, and advanced analytics, manufacturers gain real-time insights into inventory levels, demand fluctuations, and supplier performance. This leads to better planning, quicker response to disruptions, and improved customer satisfaction.

The Significance of It

Adopting digital technologies in manufacturing unlocks powerful benefits that drive both efficiency and innovation. By leveraging real-time data, intelligent automation, and advanced analytics, manufacturers can optimize every aspect of production—from quality control to sustainability.

- Improve product quality with real-time monitoring

- Reduce downtime through predictive maintenance

- Streamline operations with smart automation

- Accelerate time-to-market with digital twins

- Meet sustainability goals with energy optimization

Seamless Integration for Total Experience

Use Cases in Action for Manufacturing Industry

Electronics

Smart inventory systems paired with real-time demand forecasting reduce stockouts, optimize supply planning, and enhance order fulfillment efficiency.

Pharma

Digital batch tracking ensures product traceability, supports compliance with regulatory standards, and improves quality control throughout the manufacturing lifecycle.

Automotive

AI-powered quality control systems analyze every step of the assembly line, detecting defects in real time and improving production accuracy.

The Technology We Employ in Manufacturing Industry

We use a combination of cutting-edge and established technologies to spur innovation and provide flawless customer experiences. In the retail and hospitality industries, these tools enable us to modernize processes, customize interactions, and create flexible systems that can change to meet changing market demands.

Industrial IoT (IIoT)

Enable real-time monitoring with smart sensors, connected machines, and data-driven insights across the production facility.

Cloud & Edge Computing

Power smart factories with scalable infrastructure for real-time planning, control, and remote operations at the edge.

Artificial Intelligence (AI)

Automate processes with AI-driven quality checks, predictive maintenance, forecasting, and intelligent decision-making.

Advanced Analytics

Leverage production data to uncover trends, reduce waste, and improve efficiency on manufacturing workflows.

Robotics & Automation

Accelerate operations using robotic systems for assembly, material handling, packaging, and collaborative automation.

Digital Twins & Simulation

Test and optimize production systems virtually with digital replicas that support training and risk-free innovation.

What We Deliver in manufacturing Industry

Intelligent factory solutions

Automate production processes and factory operations to improve efficiency, reduce manual errors, and accelerate manufacturing workflows.

Smart supply chain

Gain end-to-end visibility, forecast demand accurately, and automate inventory decisions to minimize stockouts and overproduction.

Predictive maintenance

Use real-time machine data and AI to detect faults early, prevent unexpected breakdowns, and reduce equipment downtime.

ERP integrations solutions

Seamlessly connect manufacturing and business systems to unify data, enhance control, and enable informed decision-making.

Digital twin implementation

Simulate production environments digitally to test improvements, monitor performance, and optimize systems without physical disruptions.

Compliance and cybersecurity

Ensure secure, scalable infrastructure while meeting regulatory standards and protecting sensitive operational and customer data.

Manufacturing Industry Solutions.

Manufacturing Industry Expertise

With deep domain knowledge in industrial processes, we understand the unique complexities of manufacturing—from supply chain dependencies and production planning to compliance and equipment integration—enabling us to build highly targeted, efficient, and future-proof digital solutions that align with your operational and business goals.

Manufacturing Modular & Scalable

Our modular architecture allows you to start with focused digital initiatives and expand seamlessly across departments, plants, or regions. Whether you’re piloting Industry 4.0 solutions or scaling globally, our systems are built for flexibility, adaptability, and sustained growth—without disrupting your existing operations or infrastructure.

Resilience-Focused for Industry

We help manufacturers strengthen operational resilience through intelligent automation, real-time visibility, and predictive capabilities. Our solutions are designed to minimize risks, quickly adapt to market changes, and keep production agile—ensuring business continuity and competitive advantage in a rapidly evolving industrial landscape.

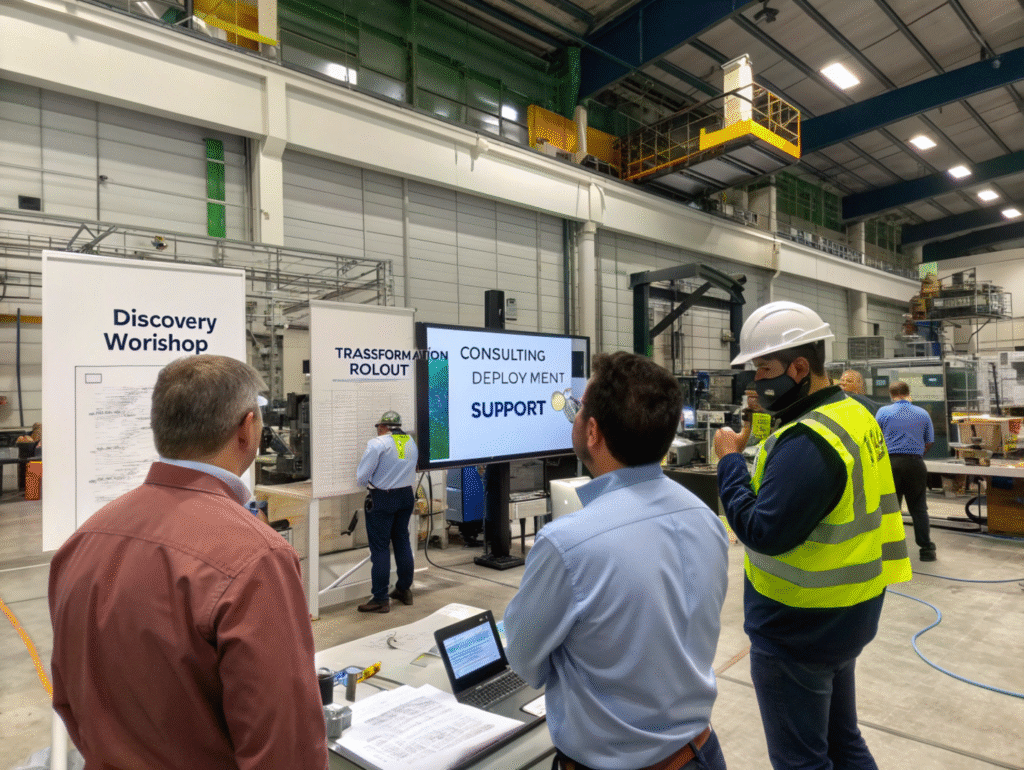

Full Lifecycle Support System Industry

We offer comprehensive support across the entire digital transformation journey—from initial discovery and consulting to solution design, deployment, employee training, and long-term maintenance. Our team stays with you at every step to ensure seamless adoption, system optimization, and continuous performance improvement.